|

There's something rather futuristic

about talking 'over' a laser beam, which is what this

inexpensive project allows. It will easily give a communication

distance of several hundred metres, and with a parabolic

light reflector, up to several kilometres. It transmits

high quality audio and the link is virtually impossible

for anyone else to tap into.

In the February 1993 issue, we described a laser beam

communicator project developed by Oatley Electronics.

It was an extremely popular project, but this latest

version not only makes the device better and simpler,

but cheaper as well. Unlike the previous version, a

visible laser diode (5mW 65Onm) is used as the transmitter.

This makes alignment between the transmitter and receiver

much simpler, as you can now see the beam. As well,

the laser has a greater output power. The circuitry

is also simpler, and uses basic components.

As before, there are two sections: the transmitter

board and the receiver board, both powered by a separate

9V battery or a fixed voltage power supply, depending

on your needs. The transmitter board has an electret

microphone module at one end, and the laser diode at

the other end. The electronics modulates the intensity

of the laser beam according to the output of the microphone.

The laser diode has an inbuilt collimating lens, and

is simply a module that connects to the transmitter

board. The previous design required brackets for the

laser diode assembly.

The receiver uses a photodiode as the receiving element,

and the onboard amplifier powers a small 4-36 ohm speaker.

This board is therefore a high gain amplifier with a

basic audio output stage.

But what about results - are they better? Sure. Because

this design uses a higher power (and visible) laser

beam, the range is improved, and alignment is easier

and not all that critical, especially over a few hundred

metres. The quality of sound transmit ted by the link

is quite surprising.

As a simple test, we set up the prototype with the transmitter

microphone near a radio. The received sound was clear

and seemed to cover the full audio bandwidth. We haven't

tried feeding an audio signal directly to the transmitter,

but that will undoubtedly give even better results.

So clearly, this project is ideal for setting up a speech

channel between two areas, say adjacent houses, or offices

on opposite sides of the street. Or you could use it

as a link between the work shop and the house. For duplex

(two way) communication, you'll obviously need two laser

'channels'.

An important feature of transmission by laser beam is

privacy. Because a laser beam is intentionally narrow,

it's virtually impossible for someone to tap into the

link without you knowing. If someone intercepts the

beam, the link is broken, signalling the interception.

Fibre-optic cables also have high security, as it's

very difficult to splice into the cable without breaking

the link. However it's theoretically possible; so for

the highest security, you probably can't beat a line-of-sight

laser beam.

You can also use an infrared laser, as in the previous

project. While this gives even better security, as you

can't see the laser beam without special IR sensitive

equipment, it also makes alignment more difficult. (An

IR laser diode is available for the project; see end

of article for details.)

fig.1 (above): The circuit for

the transmitter. The output of the microphone is amplified

by IC2a, which feeds the modulating transistor Q1, which

varies the laser current according to the signal. The

quiescent current of the laser diode is set by VR1.

The Receiver

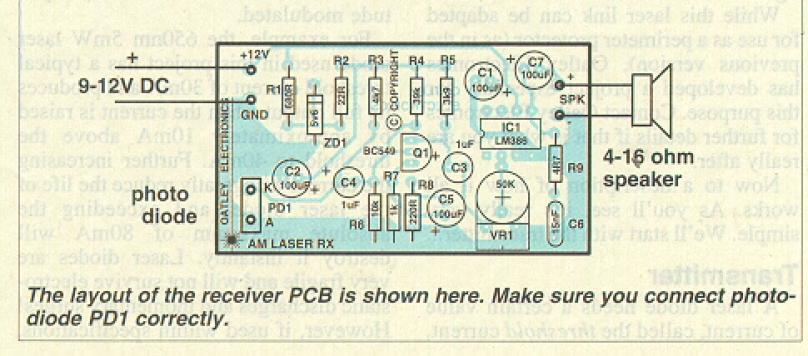

fig2 (above): The circuit for the receiver, where light

from the transmitter is detected and converted to a

voltage by the photodiode. The signal is amplified by

Q1 and IC1, which drives the speaker.

Where the transmission distance is no more than metre

of so, a LED (or two for increased power) can be substituted

for the laser diode. For instance, where the link is

being used for educational purposes, such as demonstrating

fibre-optic coupling, or the concept of communication

over a light beam. Obviously the security of the transmission

is much lower as LEDs transmit light in all directions.

While this laser link can be adapted for use as a perimeter

protector (as in the previous version), Oatley Electronics

has developed a project especially for this purpose.

Contact Oatley Electronics for further details if that

is what you are really after.

Now to a description of how it all works. As you'll

see, it's really very simple. We'll start with the transmitter...

Transmitter

A laser diode needs a certain value of current, called

the threshold current, before it emits laser light.

A further increase in this current produces a greater

light output. The relationship between output power

and current in a laser diode is very linear, once the

current is above the threshold, giving a low distortion

when the beam is amplitude modulated. For example, the

65Onm 5mW laser diode used in this project has a typical

threshold current of 3OmA and produces its full output

when the current is raised by approximately 1OmA above

the threshold to 4OmA. Further increasing the current

will greatly reduce the life of the laser diode, and

exceeding the absolute maximum of 8OmA will destroy

it instantly. Laser diodes are very fragile and will

not survive electrostatic discharges and momentary surges!

However, if used within specifications, the typical

life of one of these lasers is around 20,000 hours.

In the transmitter circuit (Fig.1) the laser diode is

supplied via an adjustable constant-current source.

Since the lasing threshold also varies with temperature,

a 68ohm NTC thermistor is included to compensate for

changes in ambient temperature. Note that the metal

housing for the laser diode and the lens also acts as

a heatsink. The laser diode should not be powered without

the metal housing in place. The quiescent laser diode

current is controlled by Q2, in turn driven by the buffer

stage of 1C2b. The DC voltage as set by VR2 appears

at the base of Q2, which determines the current through

the transistor and therefore the laser diode. Increasing

the voltage at VR1 reduces the laser current. The setting

of VR1 determines the quiescent brightness of the laser

beam, and therefore the overall sensitivity of the system.

The audio modulation voltage is applied

to the cathode of the laser diode, which varies the

laser current around its set point by around +/-3mA.

The modu- lation voltage is from the emitter of Q 1,

which is an emitter follower stage driven by the audio

amplifier stage of 1C2a. Diodes D4 to D7 limit the modulating

voltage to +/-2V, while C4 and C5 block the DC voltages

at the emitter of Q 1 and the cathode of the laser diode.

The audio signal is coupled to the laser diode via R10,

which limits the maximum possible variation in the laser

diode current to a few milliamps

LED1 gives an indication of the modulating voltage.

Diodes D2, D3 and resistor R8 limit the current through

the LED and enhance the brightness changes so the modulation

is obvious. The LED flickers in sympathy with the sound

received by the microphone, giving an indication that

a modulating volt- age is present

The inverting amplifier of 1C2a includes

a form of compression, in which the output level is

relatively constant and independent of how soft or loud

the audio level is at the microphone. This is achieved

by FET Q3 and its associated circuitry.

The cascaded voltage doubler of C9, D8, D9 and C8 rectifies

the audio signal at the emitter of Ql, and the resulting

negative DC voltage is fed to the gate of Q3. An increase

in the audio signal will increase the negative bias

to Q3, increasing its drain-source resistance. Because

the gain of 1C2a is determined by R7 and the series

resistance of R5 and Q3, increasing the effective resistance

of Q3 will lower the gain.

Since the compression circuit takes time to respond,

the clamping network of D4-D7 is still needed to protect

against sudden voltage increases. This system is rather

similar to the compression used in portable tape recorders.

The electret microphone is powered

through R1 and is coupled to the non inverting input

of 1C2a via C6. This input is held at a fixed DC voltage

to give a DC output to bias Ql.

The supply voltage to the transmitter circuit is regulated

by ICI, a 5V three terminal regulator.

Receiver

The transmitted signal is picked up

by the photo detector diode in the receiver (shown in

Fig.2). The output voltage of this diode is amplified

by the common emitter amplifier around Ql. This amplifier

has a gain of 20 or so, and connects via VRI to ICI, an

LM386 basic power amplifier IC with a gain internally

set to 20.

This IC can drive a speaker with a resistance as low as

four ohms, and 35OmW when the circuit is powered from

a 9V supply. Increasing the sup- ply voltage will increase

the output power marginally.

The voltage to the transistor amplifier stage is regulated

by ZD I to 5.6V, and decoupled from the main supply by

R2 and C2. Resistor R3 supplies forward current for the

photodiode. (Incidentally, the photodiode used for this

project has a special clear package, so it responds to

visible light, and not just infrared.)

Construction

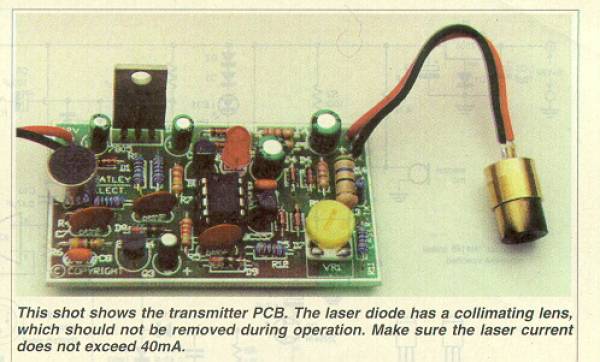

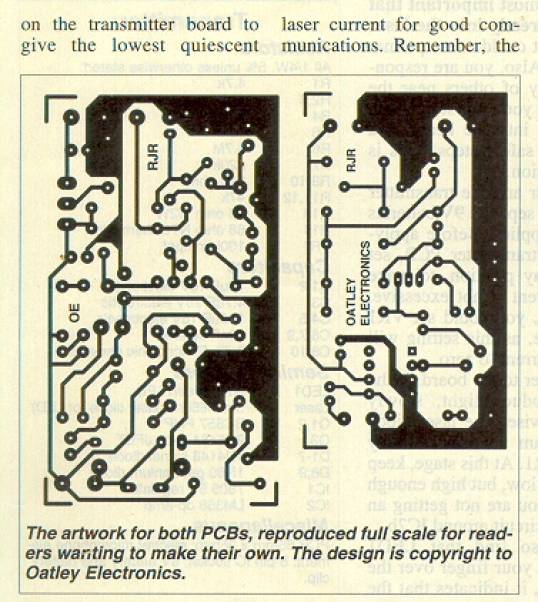

As the photos show, both the transmitter and the receiver

are built on silk- screened PCBS. As usual fit the resistors,

pots and capacitors first, taking care with the polarity

of the electrolytics. IC sockets are not essential,

although servicing is obviously made easier if they

are used. In which case, fit these next, followed by

the transistors, diodes and the LED.

Take care to use the right diodes for D8 and D9. These

are larger than the 1N4148 types, and have two black

bands (the cathode end) around a glass package. Note

that the regulator IC has the tab facing outwards.

The photodiode is mounted directly on the receiver PCB.

When first mounted, the active side of the diode (black

square inside the package) will face towards the centre

of the board. You then bend the diode over by almost

180' so the active surface now faces outwards.

The polarised microphone element solders directly to

the transmitter PCB. The negative lead is marked with

a minus sign and is the lead that connects to the metal

case.

The laser diode is also polarised, and has three leads.

Of these, only two are used, shown on the circuit as

pins 2 (cathode) and 3 (anode). Take care when soldering

the laser in place, as too much heat can destroy it.

The diode can be mounted on the board, or connected

with leads to it.

Finally, connect the speaker and 9V battery clips, then

check over the boards for any soldering errors or incorrectly

installed components.

Testing

First of all, it's most important that you don't look

directly into the laser beam. If you do, it could cause

perma- nent eye damage. Also, you are respon- sible

for the safety of others near the laser, which means

you must stop others from also looking into the beam,

and take all necessary safety steps. This is covered

by legislation.

Both the receiver and the transmitter can be powered

by separate 9V batteries or suitable DC supplies. Before

apply- ing power to the transmitter PCB, set VRI to

its halfway position, to make sure the laser current

is not excessive. To be totally sure, you could set

VRI fully anticlockwise, as this setting will reduce

the laser current to zero.

Then apply power to the board. If the laser doesn't

produce light, slowly adjust VRI clockwise. The laser

diode should emit a beam with an intensity adjustable

with VRI. At this stage, keep the beam intensity low,

but high enough to clearly see. If you are not getting

an output, check the circuit around IC2b.

You should also find that LED 1 flickers if you run

your finger over the microphone. If so, it indicates

that the amplifier section is working and that there's

a modulation voltage to the laser diode. You won't see

the laser beam intensity change with the modu- lating

signal.

To check that the system is working, place the two PCBs

on the workbench, spaced a metre or go apart. You might

need to put a sheet of paper about 2Omm in front of

the photodiode to reduce the intensity of light from

the laser beam. Set the volume control of the speaker

to about halfway. If the volume control setting is too

high you'll get acoustic feedback.

Move the laser diode assembly so the beam points at

the receiver's photodi- ode. It's useful to adjust the

beam so it's out of focus at the photodiode, to make

alignment even easier. You should now be able to hear

the speaker reproducing any audio signal picked up by

the microphone. When the receiver and transmitter are

in close range, the strength of the beam can cause the

receiver to respond even if the laser beam is not falling

on the photodiode.

Setting up a link

Once you've tested the link, you'll probably be keen

to put it to use. For a short link of say 100 metres,

all you need do is position the receiver so the laser

beam falls on the photodiode. Once the link is established,

adjust VRI higher the laser current, the shorter will

be its life.

If you have an ammeter, connect it to measure the current

taken by the trans- mitter board. Most of the current

is taken by the laser, so adjust VRI to give a total

current consumption of no more than 45mA.

Also, focus the laser so all of the beam is striking

the photodiode. At close range, there's probably no

need to focus the beam. In fact, because of the high

output power (5mW) of the laser diode, excellent results

will be obtained over reasonably short distances (20

metres or so) with rough focusing and quiescent current

adjust- ments. But the longer the dis- tance between

the transmitter and the receiver, the more critical

the adjustments. For example, for distances over 20

metres, you might have to put a piece of tube over the

front of the photodi- ode to limit the ambient light

falling on it. This diode is responsive to visible light,

so a high ambient light could cause it to saturate.

For very long distances, say a kilome- tre, you'll probably

need a parabolic reflector for the laser beam, to focus

it direct- ly onto the photodiode.

For short ranges (a metre or so), or for educational

or testing purposes, you can use a conventional red

LED. Adjust the quiescent current with VR1. The light

output of a LED is not focused, and simply spreads everywhere,

so a reflector might help the sensitivity. Warnings

The laser diode in this project is a class 3B laser

and you should attach a warning label to the trans-

mitter. Labels will be sup- plied by Oatley Electronics.

Remember that, as for any hazardous device, the owner

of a laser is responsible for its proper use.

Transmitter:

Resistors

All 1/4W, 5% unless otherwise stated:

Rl 4.7k

R2,3 1 00k

R4 68k

R5 10k

R6 4.7M

R7 220k

R8-1 0 220 ohm

Rl 1,12 47k

R13 56 ohm 1/2W

R14 68 ohm NTC thermistor

VR1 1 00k trimpot

Capacitors

Cl,2 1OuF 16V electrolytic

C3 4.7uF 16V electrolytic

C4,5 10OuF 16V electrolytic

C6,7,9 68nF ceramic

C8,1 0 0.47uF monolithic ceramic

Semiconductors

LED1 5mm green LED

Laser 5mW/65Onm laser diode (or LED)

Ql,2 BC557 PNP

03 2N5484 N-ch JFET

Dl-7 1N4148 signal diode

D8,9 1 N60 germanium diode

lci 7805 5V regulator

1C2 LM358 op-amp

Miscellaneous

PCB 65mm x 36mm; electret microphone element;

8-pin IC socket; 9V battery and battery clip.

Receiver:

Resistors

All 1/4W, 5% unless otherwise stated:

Rl 680 ohm

R2 22 ohm

R3 4.7k

R4 39k

R5 3.gk

R6 10k

R7 1 k

R8 220 ohm

Rg 4.7 ohm

VR1 50k trimpot

Capacitors

Cl,2,5,7 10OuF 16V electrolytic

C3,4 1 uF 16V electrolytic

C6 15nF polyester

Semiconductors

Qi BC549 NPN

ici LM386 power amp

ZD1 5.6V 40OmW zener

Miscellaneous

PCB 36mm x 64m; photodiode with clear

casing; 9V battery and battery clip, 4-16 ohm

speaker; 8-pin IC socket.

:: Copyright to this project is retained by

NeoLuc ® Electronics. :: Contact: NeoLuc@NeoLuc.Ro

|